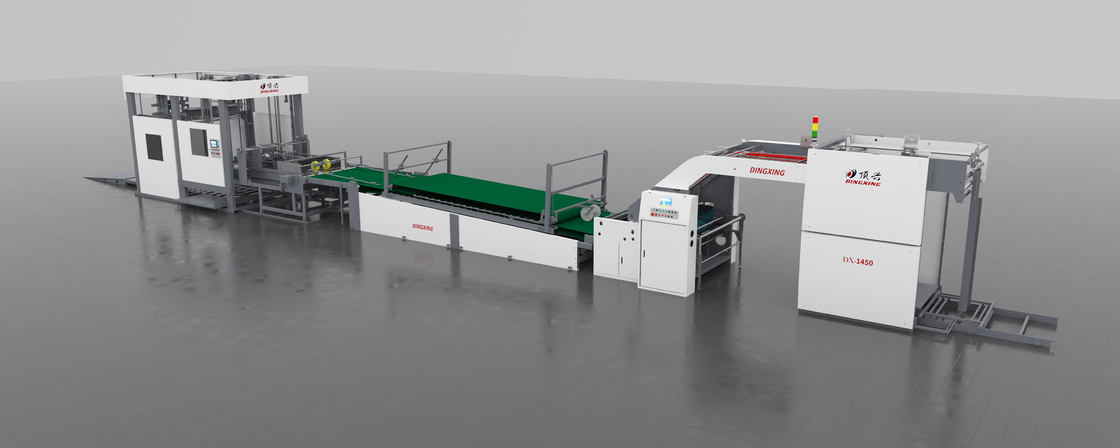

Automatic Flip Flop Stacker

In order to achieve best efficiency for High Speed Laminator, this flip flop stacker is to track the speed of the laminator and collect laminated sheets in piles neatly and automatically, and be integrated into one production line with flute laminator to increase efficiency.

Description:

1, Integrated with flute laminator to ensure automatic collection, stacking of laminated sheets.

2,Fully intermittent turning, flip-flop stacking sheets into an organised and smooth piling.

3, Stacked by one pile of up and one pile of down or two piles up and two piles down subject to paper thickness and job request.

4.Automatic paper pile height setting.

5.Touch screen operation, user-friendly and easy to run.

6 Time-saving, labor-saving and production efficient.

7. Max speed is 10000 sheets per hour.

Specifications:

| Model |

FZ-1650L |

| Max. Sheet Size |

1650(W)*1650(L)(mm) |

| Min. Sheet Size |

600(W)*600(L)(mm) |

| Max. Speed |

6000-1000Sheets/hour (Subject to paper quality and size) |

| Total Power Required |

5.8KW |

Specifications are subject to change without notice

Laminated Sheets Separation System

Main purpose is to separate the heavily overlapped sheets from pressing conveyor of laminator and deliver laminated sheets to paper collection system

Pre-stack System

Pre-stack system is to collect with laminated sheets separation system, and stack one pile of sheets neatly and deliver to flip flop system. Stack height is adjustable by entering number of sheets into HMI and paper push is driven by motor

Touch Screen (HMI)

To enter paper size, paper quantity and start the machine running.

Paper Flip Flop System

Paper Loosening System

Paper Lifting System

Paper lifting system is driven by Innovance servo motor

Paper Collecting System

Paper Delivery System

Control Cabinet

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!